Power supply surge protection for industrial control panels is not just a recommended practice but an essential legal requirement, a mandatory measure to protect electrical systems. Typical control panels are usually equipped with backup fuses larger than 315A, and the distribution board's surge protector works alongside the backup fuses. These backup fuses have high demands on cable length and protection levels, making the installation of surge protectors particularly important.

Control panels can be seen as central power hubs connecting various electrical devices, making them susceptible to events such as lightning strikes and surges that can lead to equipment damage, surge interruptions, and downtime losses. Here are the main benefits of power supply surge protection for industrial control panels:

Surge protection effectively prevents overvoltage from entering the electrical infrastructure through the control panel, extending the lifespan of the equipment and avoiding costly damage and interruptions.

Surge protection helps prevent faults caused by power surges, ensuring continuous operation of industrial and commercial facilities. This is especially crucial for critical production and operational environments.

Surge protection reduces the risk of fires and personal injuries that surges might cause, ensuring workplace safety is a top priority.

In the long term, surge protection significantly reduces costs by lowering equipment replacement costs, reducing downtime losses, and cutting maintenance expenses.

Given these significant advantages, it is crucial to install surge protection devices in the control panel's distribution board. Surge protectors in the main distribution box can discharge most of the overcurrent, but relying solely on the main distribution box's protection may not fully protect the entire system, as residual energy could still reach sensitive electronic equipment. Therefore, terminal surge protectors must always be installed close to the equipment.

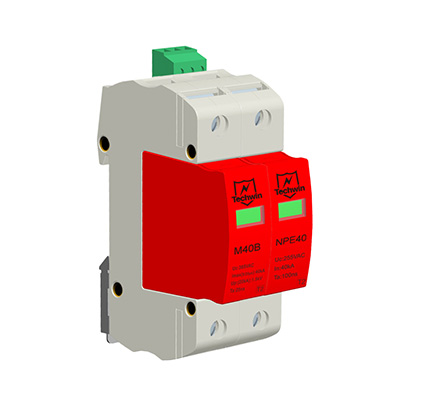

Installing a Type 1 SPD at the entry point of the electrical system as the first line of defense against voltage spikes and surges entering the electrical system is crucial. This primary protection measure effectively prevents surges from further spreading into the building's wiring system and eventually reaching sensitive electronic equipment.

The closer the distance between the surge protector and the main power source, the more effective the protection. Installing surge protectors at the entry point can significantly reduce the risk of voltage spikes affecting sensitive equipment.

However, it is impossible to discharge 100% of overvoltage at once, requiring the installation of Type 2 SPD close to the equipment for precise protection of sensitive equipment.

The faster the response of the surge protector to transient events, the better it can transfer excess energy away from the equipment. Installing surge protectors close to the equipment can shorten the distance a surge must travel before encountering the protection device.

Tailor-made Type 2 SPDs for specific circuits or devices are usually installed near the equipment for more precise protection of each circuit or device. These protective devices must be installed in series with the main surge protector to ensure effective protection at all levels during a surge event.

If a surge protector exceeds its capacity limit, it may be damaged due to a short circuit. Additional protective devices must be installed in series upstream of Type 2 SPD.

A short circuit occurs when a low-resistance connection is accidentally established between two conductors in the electrical system.Type 2 SPD must have a short-circuit current rating (ISCCR) at least equal to the short-circuit current at the connection point.

When the main distribution box uses a TN-C system, a maximum distance of 3m is required, and another 0+0.5 configuration lightning protector is needed.

Circuit Breaker vs. Surge Protector: Understanding the DifferencesSeptember 11, 2023In the world of electrical safety and protection, two commonly used devices often get confused: circuit breaker vs surge protector. While they both serve critical roles in safeguarding your electrical...view

Circuit Breaker vs. Surge Protector: Understanding the DifferencesSeptember 11, 2023In the world of electrical safety and protection, two commonly used devices often get confused: circuit breaker vs surge protector. While they both serve critical roles in safeguarding your electrical...view Efficiency Unleashed: The Impact Of Power Supply Protection Devices On Energy ConsumptionJanuary 10, 2024As the world strives towards sustainable practices and energy efficiency, the role of power supply protection devices emerges as a central force in minimizing energy consumption. These unsung heroes s...view

Efficiency Unleashed: The Impact Of Power Supply Protection Devices On Energy ConsumptionJanuary 10, 2024As the world strives towards sustainable practices and energy efficiency, the role of power supply protection devices emerges as a central force in minimizing energy consumption. These unsung heroes s...view Technical characteristics of SPDSeptember 8, 2021The important technical characteristics of SPDMaximum continuous operating voltage UCThe maximum continuous operating voltage (old: rated voltage) is the maximum root mean square value (rms) of the al...view

Technical characteristics of SPDSeptember 8, 2021The important technical characteristics of SPDMaximum continuous operating voltage UCThe maximum continuous operating voltage (old: rated voltage) is the maximum root mean square value (rms) of the al...view Power Surge Monitoring Device: Intelligent Monitoring and Power ProtectionOctober 9, 2024In modern life, electricity has become the cornerstone of our daily life and work. However, with the increasing complexity of the power network and the presence of unforeseen factors such as lightning...view

Power Surge Monitoring Device: Intelligent Monitoring and Power ProtectionOctober 9, 2024In modern life, electricity has become the cornerstone of our daily life and work. However, with the increasing complexity of the power network and the presence of unforeseen factors such as lightning...view Surge Protector Safety TipsFebruary 29, 2024When it comes to protecting your electronics from harmful power surges, surge protectors are an essential tool. These devices help regulate the flow of electricity to your devices, preventing damage f...view

Surge Protector Safety TipsFebruary 29, 2024When it comes to protecting your electronics from harmful power surges, surge protectors are an essential tool. These devices help regulate the flow of electricity to your devices, preventing damage f...view Emerging Trends in Signal Surge Protector TechnologyFebruary 29, 2024As technology continues its relentless evolution, the realm of signal surge protectors is undergoing transformative changes. The surge protection landscape is witnessing innovative advancements driven...view

Emerging Trends in Signal Surge Protector TechnologyFebruary 29, 2024As technology continues its relentless evolution, the realm of signal surge protectors is undergoing transformative changes. The surge protection landscape is witnessing innovative advancements driven...view